Portfolio

Medical, Pharmaceutical and Scientific

Medical, pharmaceutical and scientific products and equipment

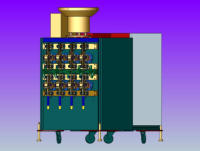

Diffcore SPM (2001 - 2002)

Commissioned

to

design

four

special

purpose

pharmaceutical

machines

to

FDA

regulatory

requirements

for

use

in

a

sterile

manufacturing

environment

and

complying to GMP requirements and proofed to a minimum of IP65.

In

essence

each

machine

will

be

identical

in

operation,

however,

each

machine

must

be designed to operate in disparate geographical areas.

Each tablet is coated in a non soluble barrier material of 0.1mm thickness.

Each

tablet

is

to

have

the

coating

removed

in

a

specific

area

on

both

sides

to

allow

controlled release of the drug.

When

each

tablet

is

“drilled”

to

remove

the

coating

it

is

important

that

the

depth

of

the

hole

is

controlled

to

within

0.01mm

to

ensure

that

a

minimum

amount

of

active

ingredient is lost and thus dust and wastage is kept to a manageable level.

Each machine is to be capable of processing a minimum of 100,000 tablets per hour.

Filtered Water Dispensing Unit For Laboratory Use (2005)

Commissioned

to

take

the

conceptual

prototype

and

create

production

ready

part

and

assembly

drawings

and

a

fully

detailed

BOM

in

readiness

for

volume

manufacture.

Design and Detail Filter Systems for two sizes of Biological Safety

Cabinet (2005)

Commissioned

to

produce

3D

designs

and

2D

details

for

the

manufacture

by

fabrication

of the above products.

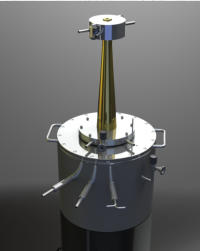

Cryogenic Test Equipment (2006)

Design

and

fully

detail

for

manufacture

cryogenic

equipment

for

testing

tessellating

terahertz radar absorbing materials.

Haemo-Dialysis Cartridge (2009)

Commissioned

to

design

a

Dialysis

Cartridge

for

a

Portable

Kidney

Dialysis

Machine

based upon the clients current technology and prototypes.

Keeler Ophthalmoscope body (2000)

•

Commissioned to Design and develop a low cost

Ophthalmoscope body for use “in the field”.

•

The product should be self powered

•

·Able to accept all existing “heads”

•

·Robust and durable

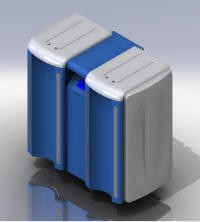

A Range Of Water Purification Units To Purify

60—125 Litres Per Hour(2010)

Commissioned

to

take

the

conceptual

prototype

and

create

a range of 4 variants.

All

4

variants

were

fully

detailed

ready

for

manufacture.

All

parts

sub-assemblies

and

assemblies

were

modelled

in

3D

with fully detailed drawings and a fully detailed BOM.

All

assembly

data

was

integrated

in

the

sub-assembly,

assembly and General Arrangement drawings.

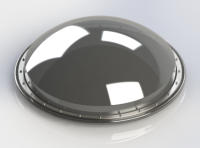

Radome (2017)

Commissioned

to

produce

“a

rough

guide

to

manufacturing

feasibility

and

order

of

magnitude cost for 1 item, and batches of 10 items”.

Following

the

completion

of

the

“Project

Definition”

document

some

assumptions

had to be made in order to complete the study, namely:

4 possible methods of manufacture would be investigated;

•

Rotational (Roto)-moulding,

•

Vacuum (Vac)-Forming,

•

GRP

•

PU Foam.

Part files (3D and 2D CAD) for each method have been generated.:

Roto-Moulded

•

Half wave

•

GRP; Thin Wall High Dielectric

•

PU; Quarter Wave

•

Vac-Formed; Low Dielectric

Additional

Part

files

(3D

and

2D

CAD)

have

been

generated

to

establish

a

possible

sealing

arrangement

and

mounting

arrangement

to

the

vehicle.

This

includes

additional

bespoke

metal

and

rubber

parts

-

as

well

as

off

the

shelf

fasteners.

Resistance

to

any

specific

chemicals

was

not

indicated

–

so

only

resistance

to

general

chemicals

used

in

vehicle

cleaning

were

considered.

Resistance

to

any

specific

forces

was

not

indicated

–

so

only resistance to general impacts from road debris would be considered.

FOCUS:

This

report

will

concentrate

mainly

on

the

design

and

manufacturing

feasibility

for

the

RADOME,

and

although

important,

the

additional

parts

can

be

classified

as

general

mechanical

engineering

parts

–

and

as

such

do

not

require any special treatment.

Enclosure End panels (2018)

Commissioned

to

design

bespoke

flat

end

panels

to

retro

fit

into

an

“off

the

shelf”

electrical enclosure.

Also commissioned to produce 10—off each part by 3D printing in ABS

AWT Limited 2019

Heat Exchanger (2020)

Commissioned

to

Design

a

Cross

Flow

Heat

Exchanger

and

to

supply

2D

drawings

and part specifications so Parts can be manufactured.