Process

First Things First

Most projects normally begin with you, the Client, approaching us with an idea for a new product. Maybe you have an existing product that you would like refreshing and bringing up to date? Or maybe you just need an additional resource to compliment your team? In any case, we would normally kick things off with a face to face meeting to discuss your requirements, often followed by a “brainstorming” session to get the feel of your product and what is required to bring the project to fruition on time in specification and in budget. The next step is to disceminate the details from our discussion and come back to you with some ideas of the direction to go. This could be with the aid of sketches, mood boards etc, or it could be we go direct into CAD designs.

Briefing

The briefing meeting allows us to find out about your product ideas and give you some initial feedback. We will listen carefully to what you are hoping to achieve and then ask a few questions of our own. Then between us we will complete a product design specification document, this will be the basis for our initial design study as it is a comprehensive checklist that makes sure we’ve got all the information we need.

CAD

All development stages can be undertaken at AlphaWave, from simple part design to whole projects. Using SolidWorks CAD and our expertise to speed up the development time and potentially reduce manufacturing costs. The CAD data is used to transform your ideas into fully featured Products in terms of assembly and function. Once development is under way in 3D CAD the data can be used to produce either virtual models or physical prototype models. The 3D data is used to carry out flow and FEA analysis where necessary it also drives the tooling design whether it be for injection moulding, blow moulding or any other process. This means that your product can be in your hands quickly and available to test in the real world. AlphaWave specialises in providing engineering design for both simple parts or more complex products in which a high level of technical expertise is required, we aim to deliver solutions that embrace the form and function as well as design for manufacturing, assembly and recycling as well as packaging and distribution issues.

PROTOTYPING

Nothing brings you closer to the final product than prototyping. Sure, you can evaluate a product inside your PC using FEA, etc. but “virtual reality” can’t give you the feel and texture of the product. It is the prototype that brings to life that “user experience”. The design may look great on the screen, but you won’t know if it works on end users until they touch, feel and use it, the prototype allows this. Not only do prototypes help provide proof of concept, they more importantly expose any usability flaws behind the design.In House:

In house we can generate one off rapid prototypes and small batches using our ULTIMAKER 3D Printer. The maximum build size we can handle is 220mm x 220mm 315mm high.Outsourced:

For larger sized prototypes we can outsource either rapid or conventional prototypes from one of our technology partners.

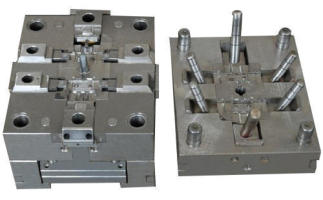

TOOLING

Once the design has been validated, the next stage is tooling, weather you go for prototype tooling as a first step, or you go directly in to production tooling is up to you. In either case we can design the tooling for you, or oversee tooling design from a third party manufacturer and arrange tool trials and “0” series production.

MANUFACTURING

Once you decide to take the next step you need to think about taking your product to market, that will include part production, assembly and packaging of your product.Production:

If you have in-house production facilities we can, at the design stage, tune your product to optimize your production facilities. If you require 3rd parties to manufacture you parts or you require, we can source vendors to do this for you.Assembly:

We design with ease of assembly in mind. If a product contains fewer parts it will take less time to assemble, thereby reducing assembly costs. If you don’t assemble in-house we can help you source someone who can do it for you.Packaging:

Weather your product is for retail, wholesale or industrial use, it will need some form of packaging, a blister, a carton or palletization. We can design ecological, sustainable packaging to compliment your product.

AWT Limited 2019