Portfolio

Leisure

Leisure products and equipment

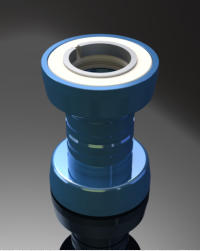

HOZELOCK Mk2 Hose End Fittings Range (1986)

Design

a

new

range

of

hose

end

fittings

to

replace

the

existing

range,

the

new

range

will

include:

Hose

Connector,

Water

Stop,

Hose

Mender,

Spray

Nozzle,

Double

Spigot,

Tap Connectors (BSP & NPT).

Responsible

for

the

design

&

development

of

the

products,

the

manufacture

&

testing

of

engineering

prototypes

&

models,

The

determination

of

product

specifications & operating parameters, Initial product costings.

The

new

design

hose

connector

contains

no

metal

parts

&

less

parts

than

it’s

predecessor, snap fits make it quick & easy to assemble.

HOZELOCK 3 Way Valve For Garden Use (1987)

Design

&

Develop

a

3

way

valve

for

garden

use,

the

product

must

be

styled

to

compliment

the

existing

“tap

end”

fittings

in

the

range,

be

cost

effective

&

ergonomically

pleasing in order to compete against competitors products.

Project Budget: £30,000.00

Responsible for:

·

The design & development of the product.

·

The manufacture & testing of engineering prototypes & models

·

The determination of product specifications & operating parameters.

·

Initial product costings.

The

design

made

use

of

“plate

valve”

technology

&

is

designed

to

operate

at

pressures

up

to

10

bar

at

ambient

temperatures.

A

significant

issue

that

had

to

be

overcome

was

the

problem

of

the

valve

plate

welding

to

the

valve

body

when

the

cap

&

body

were

assembled,

this

was

overcome

by

manufacturing

the

valve

body

in

ABS

&

the

valve

plate

in

Filled

PP,

when

the

parts

were

assembled

the

welding

operation

caused

the

PP

filler to migrate to the surface thus negating the weld at this point.

HOZELOCK Modular Pond Pump And Filter System (1988)

To design & develop a range of pond pumps & filters which are an evolution of the

current “CASCADE” range of products. The new products must establish a strong

corporate identity or "family image" the key elements of the design philosophy being:

•

Eye catching futuristic image

•

Corporate identifiable range with "family look"

•

Simple 'soft line' styling

•

Integrated modular construction of pumps & accessories

•

Commonality of major components

•

Use of lightweight plastic components

•

Incorporation of new component & manufacturing technologies where

appropriate

•

Enhancement of cost competitiveness

•

Incorporation of new USPs

•

Maintenance of traditional perception of good reliability

Project Budget: £40,000.00

Responsible for: Product styling, The design & development of the product, The

manufacture & testing of engineering prototypes & models, The determination of

product specifications & operating parameters, Initial product costings.

The project was completed to the “finalise design” stage when I left the company.

The products are now being marketed.

Design & Detail Design A New Fibre Tip Pen (Mike Devine). (2009)

Commissioned to design a revolutionary new type of fibre tip pen for kids.

Mike

Devine

is

an

inventor

who

has

come

up

with

a

unique

pen

concept,

it

is

my

remit

to

engineer

the

design

and

produce

fully

detailed

drawings

and

Stereo

lithographic parts so the client can demonstrate the pen to prospective licensees.

Bicycle Headset (2009)

Commissioned

to

design

the

part

and

produce

3D

CAD

models

so

the

client

can

demonstrate

his

product

to

prospective

investors

with

a

view

to

taking

the

parts

through to production when financial backers are in place.

Bicycle Quick Release (2009)

Commissioned

to

design

the

part

and

produce

3D

CAD

models

so

the

client

can

demonstrate

his

product

to

prospective

investors

with

a

view

to

taking

the

parts

through to production when financial backers are in place.

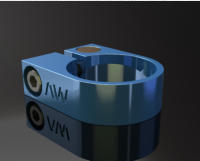

Bicycle Seat post Clamp (2009)

Commissioned

to

design

the

part

and

produce

3D

CAD

models

so

the

client

can

demonstrate

his

product

to

prospective

investors

with

a

view

to

taking

the

parts

through to production when financial backers are in place.

Energy Drink Wrist Band (2011—2012)

Commissioned

to

design

from

artists

sketches

a

strap

that

holds

a

disposable

energy

drink

“bottle”

and

produce

3D

CAD

models

so

the

client

can

demonstrate

his

product

to

prospective

investors

with

a

view

to

taking

the

parts

through

to

production when financial backers are in place.

The drink is intended for active people with Diabetes—such as swimmers.

Bath Toy (2013)

Commissioned

to

Model

in

3D

CAD

from

conceptual

sketches

the

2

variants

of

the

product

so

working

pre-

production prototypes can be manufactured.

Table (2013)

Commissioned to Design a Table to the clients specification, including:

•

Variable sized hole in table top

•

Adjustable height legs

•

Mirror with rotating feature

•

Spring loaded pedal feature

•

Able to carry 80 kg load

And

to

supply

2D

drawings

and

part

specifications

so

pre-production

prototypes

can

be manufactured.

AWT Limited 2019

Fire Pit (2020)

Commissioned to Design a range of 5 Fire Pits to the clients specification, including:

•

Grill Tray

•

Log Store

•

Sizes from 600mm x 600mm to 1200mm x 1200mm

•

And

to

supply

2D

drawings

and

part

specifications

so

production

Parts

can

be

manufactured.

Sports Water Bottle (2020)

Commissioned to Design a Sports Water bottle including:

•

A Screw-on Cap

•

A Sliding/sealing access to drinking spout

•

A fold out storage section to keep a Gum shield

Exercise Roller Plus (2021)

Commissioned

to

Design

an

Exercise

Roller

with

integral

storage

for

additional

Items

including:

•

2 x Sliders

•

Skipping Rope

•

Mat

•

Provision to be made for additional Items in future versions

•

And

to

supply

2D

drawings

and

part

specifications

so

prototype

parts

can

be

manufactured.